Every year, supply chain disruptions cost businesses an average of $200 million. The present world situation, be it the COVID-19 pandemic or the Suez Canal choking in 2021 to the ongoing political war, has exponentially increased the risks of these disruptions. Market volatility, supplier inconsistency due to political and geographical barriers around the world, COVID and the war-hit workforce, and working in a new standard setup have hindered the regular flow of supply chains. This situation demands the supply chain to be more agile and well connected as fast as possible. The rising demand squeezes the scope of any errors and needs more accurate demand forecasting to lower the loss rate.

In recent years, most leading companies have started implementing AI/ML to leverage speedy decision making, accurate demand forecasting, better inventory management, speed in operations, dynamic logistic system, and delivery control. In a survey, Gartner said that the usability of AI and ML would double in the next five years in the supply chain. Again, as per another study, Global spending on IIoT Platforms is expected to rise from $1.67 billion in 2018 to $12.44 billion in 2024, representing a 40% compound annual growth rate (CAGR) over the next seven years.

Considering the vastness and increasing complexity of the supply chain network, it’s the need of the hour to implement an automated system to manage the entire network better.

This article will briefly discuss the change in the supply chain landscape after the pandemic, the implementation of AI/ML in the supply chain and their benefits and challenges, and the last use case of AI implemented in the Supply Chain.

Aftermath Of Supply Chain Landscape Post COVID Pandemic

COVID-19 pandemic has exacerbated the pre-existing challenges of the logistic and supply-chain industry and added a few more to that list. It changed the fundamental consumer behavior and demanded the adoption of agile ways of working.

In a survey by EY USA conducted in 2020, 97% of industrial companies revealed that the pandemic had a severe negative effect. Few sectors of the industries, e.g., the life sciences sector, did report a positive impact on their businesses during the pandemic. For instance, 11% said that their customer demand increased by 71%, and the rate of launching new products to the market increased by 57%. But the challenge is that these companies had to increase their essential product creation, e.g., COVID 19 vaccine, twice as much as before.

So overall, the pandemic demanded more resource power, intense inventory management, and, more importantly, accurate predictive analysis of the market.

Next Step for Supply Chains:

From the EY conducted survey, 60% of the executives conveyed that the pandemic catalyzed their strategic needs for the supply chain. The future supply chain demands agile, flexible, efficient, resilient, and digitally networked. The pandemic has pushed many sectors to the digital platform and workforce to work remotely. On the other hand, it made onsite resources mandatory to adopt the COVID-19 norms and work in the new normal.

The survey showed an increase in automation and AI and machine learning investments, with 37% already deploying these technologies and 36% planning to do so soon. Moreover, digital and autonomous technologies will assist in making people’s jobs more accessible and the supply chain more efficient and optimized.

How Can AI / ML Help ?

Implementing AI/ML in the supply chain has numerous benefits. Some of the significant benefits are:

Predictive Analysis: Demand Forecasting uses the power of automation to analyze all the data that the organization can collect, from demographics to price changes to consumer sentiment, and make sense of it against the sales history.

Companies can use machine learning models to enjoy the perks of Predictive Analysis for demand forecasting. These patterns analyze the historical data to identify the patterns. So, in the supply chain, the models can be used to find the issues before any disruption is caused.

A solid supply chain forecasting system means that the company has the resources and intelligence to respond to emerging issues and threats. Furthermore, the effectiveness of the response grows in direct proportion to how quickly the business can respond to problems.

Optimized Inventory Management: An appropriate AI/ML model helps any company manage the over and understocking problem, thus improving inventory management. It can analyze the customer and market demand from the survey data and enable continuous improvement in a company’s efforts to meet the desired level of customer service at the lowest cost.

You can also use AI and ML to analyze large data sets much faster and avoid human errors in a typical scenario.

Avoid Forecast Errors: The AI/ML algorithm helps organizations deal with large data sets. The data processing is done with tremendous variety and variability. IoT devices, Intelligent Transportation Systems, and other powerful technologies enable the supply chain to gather massive data. The subsequent model helps companies have better insights and achieve more accurate forecasting, preventing enormous disruption or loss. According to a survey by McKinsey, AI and ML-based supply chains can reduce forecasting error by 50%.

Improve Supply Chain Responsiveness: To minimize the cost of improved customer experience, most B2C companies are implementing AI/ML models. The AI/ML model induces automatic responses; AI chatbots help serve the customers promptly and thus handle demand-to-supply imbalances.

The data analysis power of the ML model from the historical data helps the supply chain managers to understand the customer demands and also helps in better planning of vehicle routes and goods delivery. Thus it reduces the driving time and cost and enhances productivity.

Challenges To Implementing AI/ML In Supply Chain:

COVID-19 pandemic has exacerbated the pre-existing challenges of the logistic and supply-chain industry and added a few more to that list. It changed the fundamental consumer behavior and demanded the adoption of agile ways of working.

In a survey by EY USA conducted in 2020, 97% of industrial companies revealed that the pandemic had a severe negative effect. Few sectors of the industries, e.g., the life sciences sector, did report a positive impact on their businesses during the pandemic. For instance, 11% said that their customer demand increased by 71%, and the rate of launching new products to the market increased by 57%. But the challenge is that these companies had to increase their essential product creation, e.g., COVID 19 vaccine, twice as much as before.

Data Silo: The prerequisite for any enterprise to implement the AI/ML is the classified data, and still, most organizations lack that. Still now, most companies are process-driven, run by leaders from a traditional experience background facing a significant amount of challenges to transform into a data-driven model. Most companies are vertically implemented using ERP, MRP, TMS, and WMS in the supply chain to manage their functional departments. Consequently, data related to critical information, e.g., customer or market demand, logistic, and function-specific challenges, become siloed. Cross-functional insights are one of the most vital aspects yet the most challenging one to prevent supply-chain disruption and require a massive volume of data. So, gathering unified data to make an AI/ML algorithm work properly is one of the biggest challenges before the implementation.

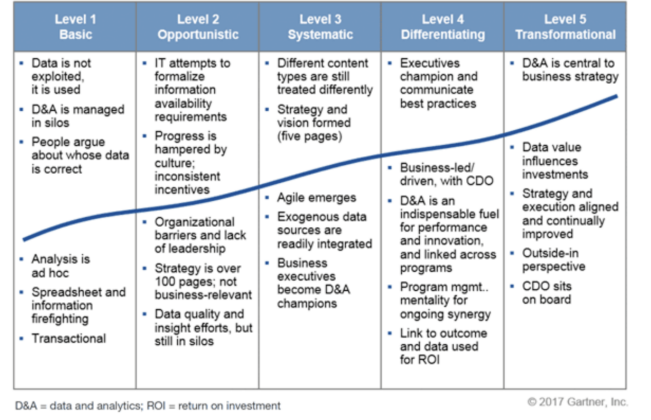

Poor Data Maturity Level: Poor data maturity level is the primary hindrance behind the AI/ML implementation in a supply chain. According to Gartner’s worldwide survey of 196 organizations, 91% of organizations are not yet at the “transformational” level of maturity in data and analytics. In Gartner’s five-step Data and Analytics Maturity model, it found that 60% of the enterprises worldwide rated themselves in the lowest three levels, i.e., Level 1(Basic), Level 2(Opportunistic), and Level 3(Systematic). Only 9% of the organizations are found at the highest level, Level 5, where the most excellent transformational benefits can be found.

Source: Gartner

Organizations reported different challenges in increasing their use of data and analytics; three significant reasons can be highlighted- defining data and analytics strategy, determining how to get value from projects, and dealing with risk and governance issues. Henceforth, we can conclude that the industry needs to come a long way on the data front to implement AI/ML in the supply chain successfully.

Use Case Of AI/ML Induced Supply Chain:

Leading companies have started implementing AI/ML in their supply chain actively. For example, Microsoft’s supply chain system relies on predictive insights powered by business intelligence and machine learning. The company has a massive product portfolio causing an enormous amount of data that must be integrated centrally for predictive analysis and driving operational efficiencies. Machine Learning techniques have enabled the company to create a seamlessly integrated supply chain system that allows them to capture and analyze data in real-time. Furthermore, the company’s robust supply chain employs proactive and early warning strategies to aid in risk mitigation and quick query resolution.

Wrapping Up –

Improving the efficiency of the supply chain is critical in any business. Any process improvement can significantly impact the bottom line profit by operating within tight profit margins. Innovative technologies such as machine learning make it easier to deal with the volatility and accurately forecast demand in global supply chains.

A Gartner survey says that, by 2023, at least half of global companies in supply chain operations will be using AI and ML-related transformational technologies. This demonstrates the increasing popularity of machine learning in the supply chain industry. However, to fully reap the benefits of machine learning, businesses must plan for the future and begin investing in machine learning and related technologies today to enjoy increased profitability, efficiency, and better resource availability in the supply chain industry