Toilet paper is perhaps the one phrase that sums up the pandemonium that was unleashed across several parts of the world when the COVID-19 pandemic first began to sweep across borders. Depending on where they were in the world, customers may associate another word with the supply chain disruption that characterized the pandemic in its early days. Many items disappeared from the shelves for weeks. Several others that were being imported from other countries remained off the shelves, as the importer permanently closed the business due to the unforeseen crisis.

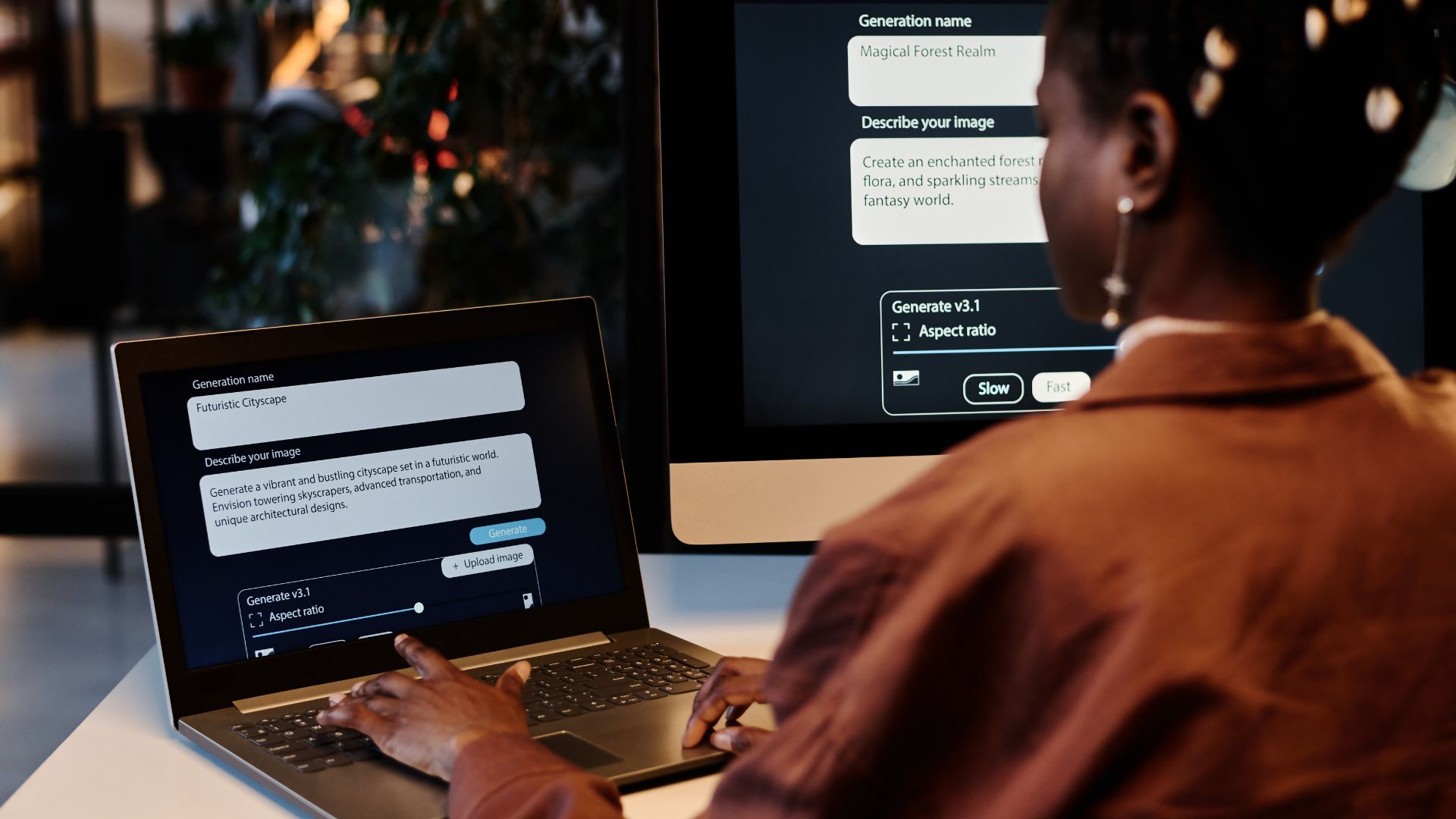

As companies today vie for competitive advantage, their ability to proactively find and deal with supply chain risks will be a critical differentiator. Although supply chain planners have been recording textual data about risks in business systems, this information is rarely used strategically. Moreover, evaluating hundreds of textual bits manually is difficult, time-consuming, and error-prone. For instance, a single product could amass over 400,000 comments in the course of a year!

This is where emerging technologies such as NLP hold immense potential by automating and providing predictive insights.

Natural Language Processing (NLP) is a combination of computer science, artificial intelligence, and linguistics that uses models to understand and find patterns in natural language. Typically, humans communicate with machines through the use of specialized programming languages or predefined answers. However, NLP transcends these limits and enables users to connect with computer systems using natural speech and writing patterns.

Natural language processing can be applied in several ways to supply chains and logistics. For instance, through training, the model begins recognizing different language patterns; analyzing this data can lead to information, insights, and even automated actions. These capabilities allow businesses to resolve supply chain risks proactively rather than reactively.

Benefits Of NLP

Capture information

Using natural language processing and unstructured data querying, it is possible to look at published material that is available to the public. This content may appear in blogs, videos, social media, news, and other formats. By keeping an eye on social media and scraping websites, businesses can be proactive and evolve their strategy. For instance, social media listening via Twitter and Facebook can be effectively tracked.

The software monitors important terms or phrases that can potentially affect the supply chain, and an algorithm analyzes and derives business intelligence from the gathered data. Thus, NLP can efficiently detect issues with certain suppliers, keep track of major environmental changes, provide insights on repercussions, verify sourcing, and monitor competition. It can also help improve supply chain governance, ethical practices, policy and procedure changes, reputation management, and other predictable trends.

Generate supply chain maps

Supply chain mapping (SCM) is the process of documenting information shared by companies, suppliers, and individuals involved in a company’s supply chain to create a global map of the entire network. For instance, the precise origin of all goods and shipments can be mapped.

Initial findings indicate that supply chain mapping solutions generated through Natural Language Processing (NLP) can help businesses:

- Automatically generate basic supply chain maps

- Validate existing supply chain maps

- Enhance current maps with extra supplier information

Leverage adaptive chatbots

Natural language processing solutions for the supply chain improve consumer-facing applications such as customer service chatbots that can engage with clients, suppliers, manufacturers, and distributors. This would reduce the amount of effort required to carry out orders and eliminate potential inaccuracies.

Chatbots can also expedite the procurement process by communicating with supply chain professionals, collecting requirements by chatting in natural language from any location, and simplifying the process for people with low technical expertise.

Monitor data changes

NLP algorithms can monitor internal data changes in real time, which can aid in maintaining accurate master data. Web scraping collects benchmark industry data for finding transportation rates, fuel, and expenses. This information assists firms in benchmarking their performance against industry standards and identifying potential cost savings.

Similarly, NLP can be used to scrape data from logistics carriers’ and shipping ports’ websites. It can analyze the impact of a crisis and suggest measures like increasing the safety stock inventory levels, adopting other modes of transportation and locating new routes to ship products. Web scraping and social media listening can also provide useful supplier data for labor relations, regional political constraints, local news about strikes or riots, and weather events that can disrupt supplier operations and result in supply risk. This data can be further evaluated to generate early warning indicators.

Improve customer service down the chain

Because supply chains generate a lot of data, finding the best way to use this data to optimize the supply chain is important. NLP allows users to ask complicated questions and guides them through the data to help them find answers. Companies can respond well to stakeholders further down the supply chain if they automate their customer service.

Using natural language processing makes automating customer service much easier. When stakeholders ask questions, NLP gives them the correct answers or points them in the right direction. Because of this, the administrative costs in customer service centers go down and customer satisfaction goes up all along the supply chain.

Capture information across multiple languages

Most businesses operate on a worldwide scale, and language constraints can impede process efficiency. Language limitations are a major concern in global supply chains and logistical performance (e.g., pickup directions and instructions for truck drivers). NLP helps resolve this issue by allowing local stakeholders to communicate in their own language. It can also analyze, organize, and translate data so that it is accessible to all users, as well as translate papers from one language to another to decrease regional language barriers.

Track compliance among suppliers

Web scraping can be used to track crucial external information about major suppliers. Monitoring a supplier’s stock market performance and reviewing its financial records, for example, can give information about the supplier’s financial stability. Furthermore, online scraping and social media listening can provide additional information about labor relations, regional political constraints, local news about strikes or riots, and weather events, all of which can affect supplier operations and increase supply risk. Using this data, early warning indicators can be generated, and supply chain organizations can reduce risks proactively by minimizing their reliance on a single source.

Wrapping Up

The outbreak of COVID-19 was a wake-up call in more ways than one for supply chain players as well as the organizations relying on them. Most organizations took far too long to bounce back, impacting their operations and bottom line. One of the biggest problems with the process was that most companies relied too much on internal data to track their demand-supply balances. This made it hard for them to predict how outside events would affect their supply chains.

Supply chain organizations must therefore go beyond their current landscape and leverage digital capabilities to develop resiliency. Natural language processing is an emerging AI application that can contribute to resiliency by transforming unstructured human language from voice or text into normalized data suitable for analysis. As a result, companies can easily monitor social media, news sources, and other web pages for external data on catastrophic events, enabling them to intervene and reinforce their supply chains sooner rather than later.