Supply chain planning is a vast field involving many departments and stakeholders using different technologies resulting in data silos. Traditional supply chain models store information in Excel spreadsheets. They maintain multiple closed ERP systems for various parts of supply planning in these sheets. Various stakeholders involved in supply planning have been using these siloed systems with little collaboration and visibility to others leading to problems like

- Overstocking and wastage of Inventory

- Non-fulfillment of demand due to low Inventory and poor buffer stock plans

Moreover, in modern supply chains, globalization increases data integration difficulties. New business models with outsourced manufacturing, acquisitions, and partnerships or joint developments with partners have blurred the divisional boundaries.Data plays an integral part in such a system, and silos put the all-over business at a greater risk. For instance, it’s harder to share demand forecasts and demand changes with the suppliers.

On the other hand, to minimize silos, having periodic on-site meetings among the teams and working on changes for hours is not cost-effective. It’s inefficient, ineffective, and costly for any last-minute changes.

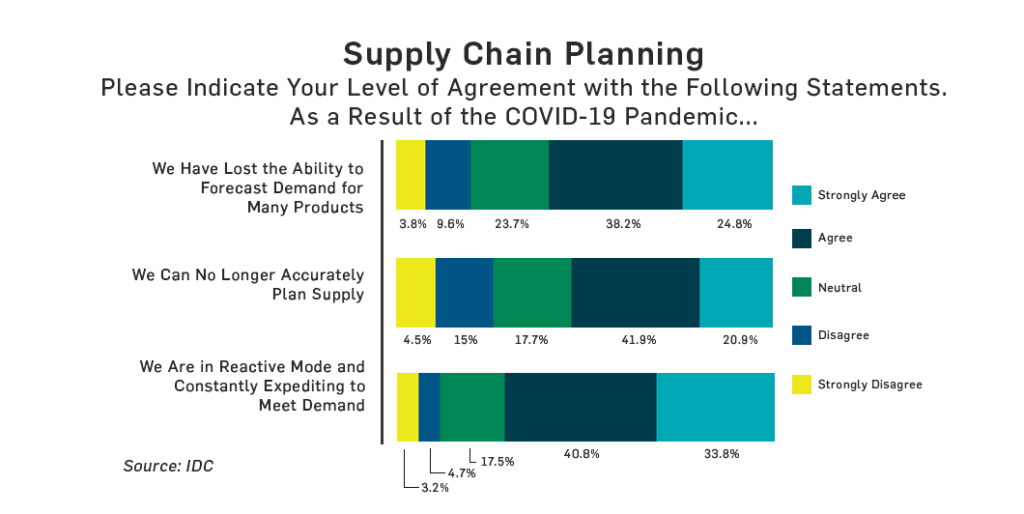

Moreover, the COVID-19 pandemic effect is continuing to sputter and break down the global supply chain. There are still many disruptions like out-of-place shipping materials and data mismanagement. IDC polled 532 companies across the pharmaceutical supply chain to assess the impact of the COVID pandemic’s supply disruptions.

This article will highlight the core reasons behind the information silos and their effect on Supply chain planning.

When does a Silo happen?

Let’s say a global company makes an important decision like entering a new market or expanding into one, and the silo happens while making decisions by individual verticals such as :

- When to buy?

- How much to buy?

- Where to buy it?

- Where to keep the inventory etc. ?

Silos happen when different verticals don’t share relevant data horizontally.

The number of verticals and divisions within a company increases along with the Company’s growth. Going by an old saying, “Too many cooks spoil the broth,” the system becomes inconsistent due to poor data sharing and management systems between teams that lead to silos.

Why does Information Silo Occur?

There are three significant reasons that can result in information silos :

- Poor Data Governance Maturity Model: Data Management and poor Data Maturity models are the most significant reasons behind the silo occurrence. The Data Maturity Model helps organizations understand their data capabilities and identify vulnerabilities and improvement areas. It also allows companies to compare their progress with peers and competitors. Any organization with a Level 0 Data Maturity Model has no defined process for data creation, gathering, or sharing. In this case, sharing data and its storage and archiving are done by email, resulting in information SILO

- Inadequate Shared Network: Without a cohesive shared data network, departments make contradicting decisions, and data is wasted and neglected, creating data silos.

- Adapt to company growth: Without proper scaling, Company’s development and the diversified verticals overwhelm infrastructure and create silos. Silo happens when data is shared vertically but not horizontally. It slows down data processing and makes a significant backlog for data managers and IT.

- Poor organizational structure: If team members cannot work together to work on data, silos will occur inevitably. An organizational structure which is not ‘data driven’ often fails to put in place processes/systems in place that could help the company harness the full potential of the captured data.

Effect of Information Silos on Supply Chain:

Modern supply chains involve multiple departments and stakeholders. The demand for quick decision-making is based on a vast amount of data. Often, a lack of communication between the departments can impact each other. United States’ food wastage is a consequence of such data silos. According to the NRDF, of the total food wastage, approximately 40% of it is contributed by the US alone, which is somewhere around $218 billion per year!

- Poor Decision Making: Logistic and transportation companies face significant problems due to the unshared and unviewed data. A company can lose opportunities, revenue, and higher production and supply costs due to the silo effect. Moreover, data impairment can trigger poor decision-making

- Disrupt Functionalities: In a multi-layered supply chain, fragmented information among the stakeholders can disrupt the functionalities. It can result in poor supply visibility, slowed or stalled innovation or collaboration, and an increased risk of unexpected events (such as missed delivery deadlines)

- Prevents building an Integrated System: Legacy software systems were not designed to support shared work across multiple enterprises. So, they create information silos that control the supply network from producing a coordinated response to issues that require team collaboration. In case of complicated problems, like, materials shortage, a last-minute manufacturing change, or a late request to increase the size of an order, the only options for multi-enterprise collaboration are email, faxes, and spreadsheets.

- Wastage of Resources: Another significant problem with information silos is the wastage of resources. Due to information fragmentation, different users download the same documents from separate storage. These data redundancy cases push the IT department to buy more storage

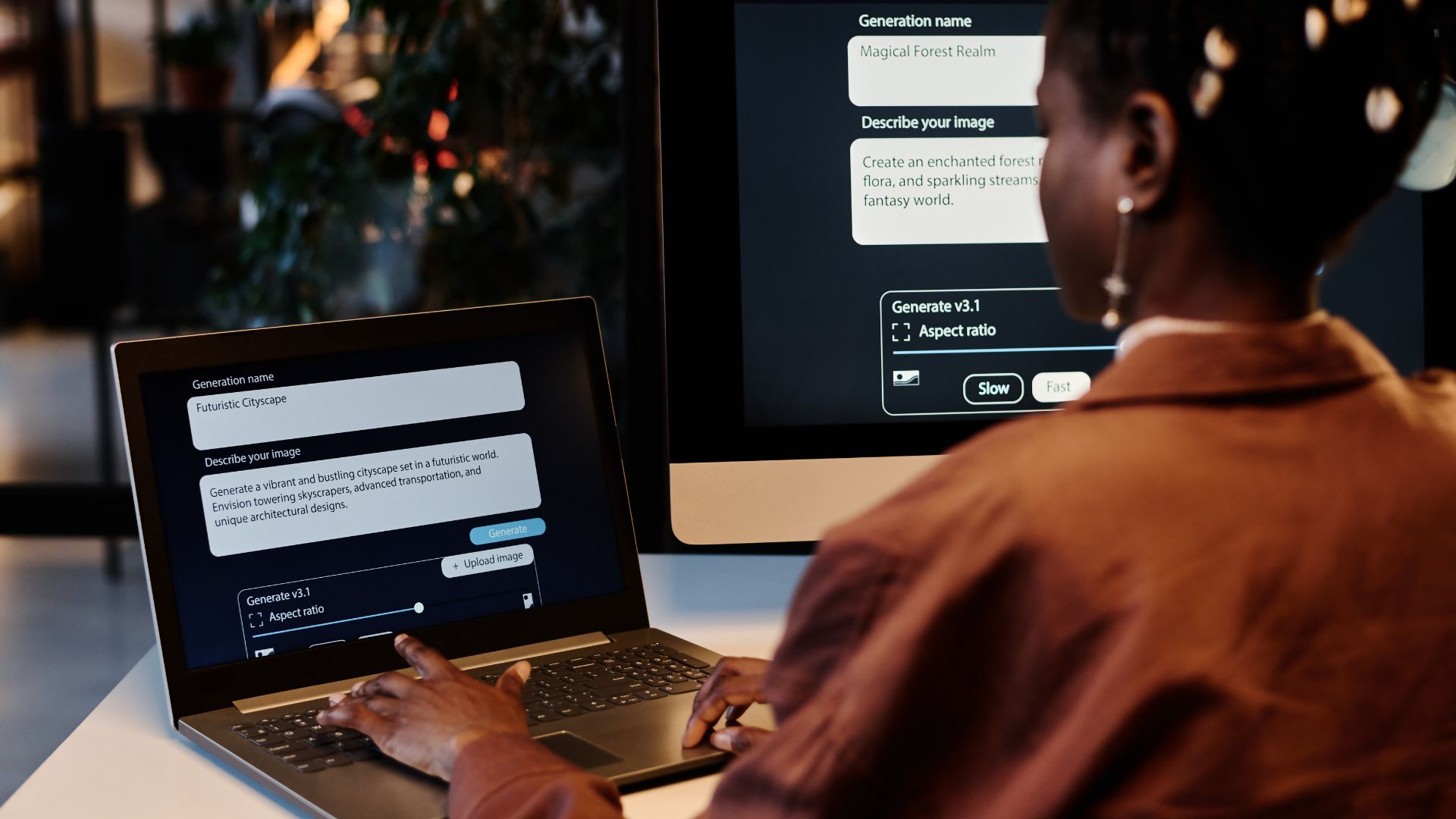

- Difficulties in Implementing AI Solutions to the Supply Chain: With the advancement of technology, building a seamless, automated system implementation of AI is evitable. But AI can’t work on diverse, scattered data. It’s essential to gather the data and classify them and to have a consistent sharing system to make an AI algorithm work optimally

Wrapping Up:

Data silos are a dilemma companies face across industries, but they can negatively impact the logistics and transportation industries. A data-driven approach would be an optimal solution to prevent Information silos. Once an organization acknowledges the lack of data governance, the next step is to recognize the necessary process, tools, and models to create an effective data governance method. This is the most critical step in implementing a data-driven procedure, and the rest will follow gradually. Even to implement an AI/ML solution to eliminate the Silo problem, having a data governance maturity model is a must. Removing supply chain bottlenecks and silos ensures that your customers’ needs are met, and it helps to make the right decisions. Overall, eliminating data silos can increase efficiency and boost your Company’s bottom line.