Demand planning is the practice of forecasting the demand for a product or service so it can better serve customers. Having the right amount of inventory without incurring shortages or spending money on surplus inventory is at the heart of demand planning. While it may seem unrealistic to expect businesses to consistently match their supply to demand without losing revenue or clients, several customers have realized this vision through AI-based demand planning.

So, what exactly is AI-based demand planning?

As the name suggests, AI-based demand planning leverages the power of artificial intelligence and machine learning to analyze sales and consumer trends, historical sales, and seasonality data through a combination of sales forecasting, supply chain management, and inventory management. By optimizing your ability to forecast demand efficiently, demand planning can become an established, continuous process that informs your sales and operations strategy.

Why Choose AI-based Demand Planning?

Utilizing ML and AI demand forecasting has numerous advantages. Adopting AI methodologies can facilitate accurate forecasting at all organizational levels. According to McKinsey, demand management in the supply chain using AI-based methods can reduce supply chain network errors by 30–50%.

Applications based on AI and ML utilize data to make predictions. The dimension reduction, cross-validation, and grid search mechanisms enable algorithms to optimize the model and minimize errors by adjusting various features and parameters. Forrester estimates that over the next two years, 55% of organizations will invest in artificial intelligence.

If you have been considering investing in AI-based demand planning, here are five good reasons to make the transition.

Top Five Benefits of AI-based Demand Planning

1 Brings accuracy to demand forecasting

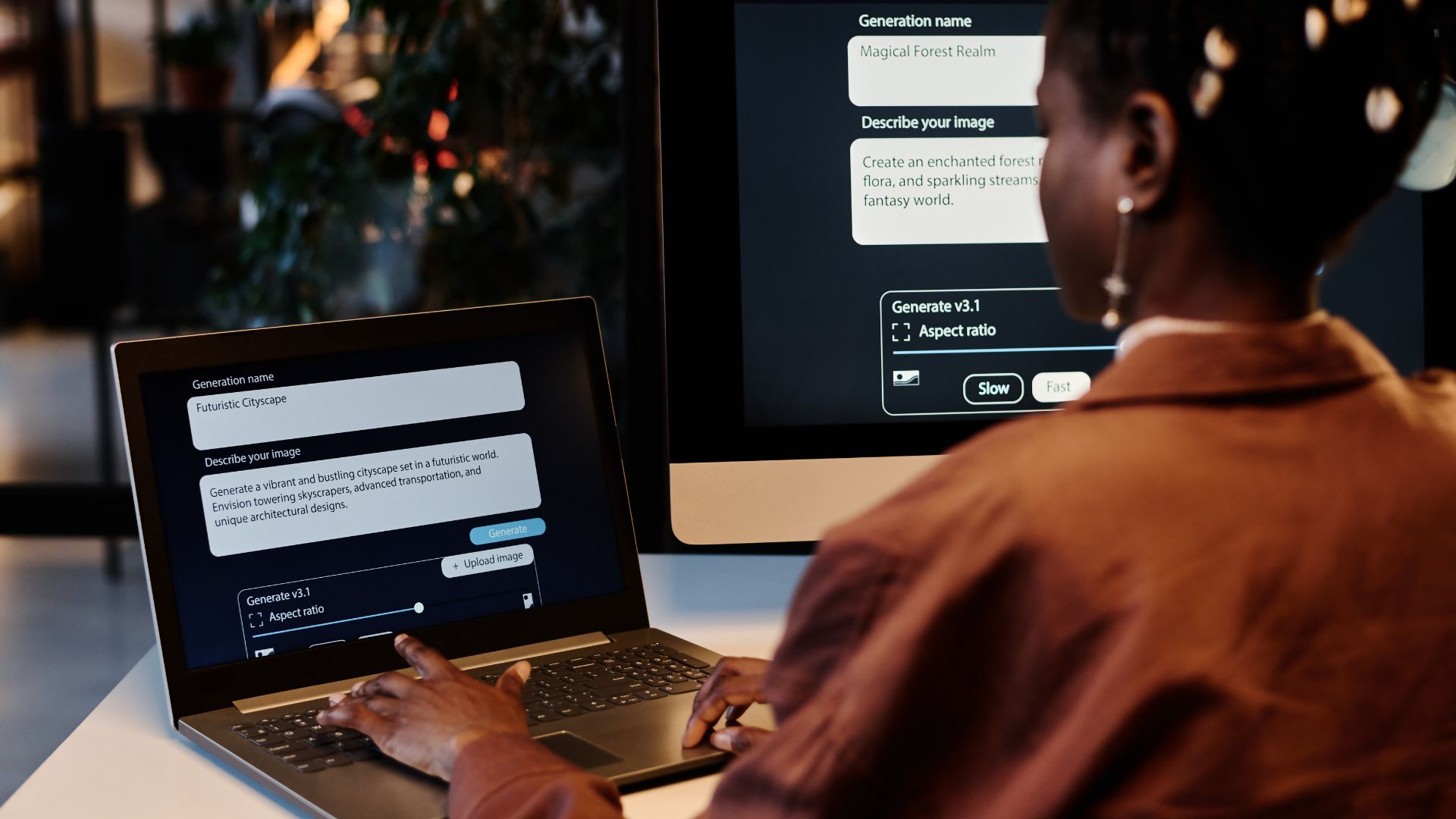

A superior AI ensures that data can be organized and analyzed in minutes. Since AI transcends historical data and is not reliant solely on rules, it requires businesses to establish fewer rules initially. With the AI handling time-consuming data preparation processes, your precision will improve. Moreover, since data is frequently updated, the results are more accurate. Thus, adopting ML and AI can help retailers harness the power of their data while retaining complete control of it.

It is also possible to deliver a unique forecast model for each product.

AI can recognize similarities, make connections, and anticipate patterns that were not initially programmed, providing supply chain professionals with a bird’s-eye view of their inventory and its underlying relationships.

Considering the importance of forecasting from a financial standpoint, retailers’ losses from missed sales or excess inventory add up quickly. With innovative solutions, it is possible to avoid overstock, understock, and out-of-stock situations.

2 Timeliness in demand forecasting

AI systems are often superior to humans when it comes to data-intensive, monotonous tasks. They can assist logistics companies and retailers in analyzing vast amounts of data, identifying inefficiencies and detecting opportunities for improvement. AI systems can analyze multiple data sets simultaneously, combing through information manually and making connections that usually take a lot of time. Therefore, they can provide results in a fraction of the time. Amazon, the leading e-commerce giant, uses AI at nearly every level of its supply chain, particularly in its warehouses. The timely AI predictions help the company fulfil orders faster than most competitors.

AI can also help optimize route planning and shipment updates, allowing companies to predict demand and supply. For instance, many companies use technologies like RFID tags to track products through the supply chain. However, sometimes items ship without these tags or events, causing them to be unreadable. Using AI, businesses can analyze things like average shipment times and weather patterns to offer accurate results.

3 Immense cost savings with the right demand planning strategy

Besides enhancing accuracy and timeliness, AI can save time, money, and productivity by taking on various administrative and data-intensive tasks. The AI handles administrative tasks, allowing human employees to focus on other projects.

For instance, manual tasks such as document filing can cost businesses 6,500 hours per year–a significant amount of time. Imagine what a business could accomplish if it had over 6,000 additional hours to work! This productivity benefit is far too advantageous for logistics companies to ignore. A logistics leader saved 100 million miles and 10 million gallons of fuel annually with AI-optimized route planning.

4 Improved customer service with demand estimation and forecasting

Chatbots, typically used in customer service roles, are one of the most common applications of AI, enabling supply chains to provide 24-hour customer service. By delegating customer engagement to artificial intelligence, logistics companies can free up human employees’ time. Not only does this improve efficiency, but it also enhances customer service by increasing the customer’s access to information.

Customers can check their order status with an application like Alexa to provide prompt and accurate responses. In addition to being a quick, hands-free information gateway, smart speakers are already common in many homes. People who are used to using these technologies will appreciate the ability to use them to learn about their orders.

5 Strategic decision-making with demand analysis and forecasting

Using AI to find outliers in demand planning makes it easier for a business to make good decisions by spotting changes early on and putting adequate measures in place at the right time. A superior AI goes even further by recommending clear courses of action that consider internal constraints and parameters. The risk of interventions that don’t work to meet demand is reduced, as are inefficiencies in the supply chain.

Supply chains must make the most of their shipping to deliver products on time. Often, this means planning the fastest, safest way to get from point A to point B. AI is ideal at making these predictions by looking at traffic and weather patterns to determine the best course of action. Since factors like these are dynamic, optimal routes may change daily. As a result, supply chains need tools like AI to analyze data and plan routes quickly.

Wrapping Up

AI demand forecasting alters how businesses manage their supply chains and make essential business decisions. Rather than relying on manual processes, AI-based demand forecasting collects, combines, and analyzes data sets to identify patterns and issues. As a result, companies can decide everything from stock purchases to price reductions based on demand forecasts supported by cold, hard data.