The manufacturing industry has evolved significantly since the 19th century, transitioning from labor-intensive, localized production to a critical driver of global economic growth powered by automation and technology. The Industrial Revolution introduced mechanized production and assembly lines, laying the foundation for modern manufacturing processes that prioritize efficiency, scalability, and precision.

By the 21st century, manufacturing accounted for an estimated 15-20% of global GDP, with a market value exceeding $44.5 trillion in 2022. Among its diverse branches, continuous manufacturing—especially in industries like steel, cement, and mining—stands out for sustaining uninterrupted production. However, the increasing complexity of manufacturing environments has elevated safety and efficiency as critical concerns.

Stackers and reclaimers play a pivotal role in these industries, handling vast quantities of materials in environments that demand precision, coordination, and resilience. Yet, shared tracks and challenging conditions pose operational risks, underscoring the need for advanced solutions that can ensure uninterrupted and safe operations.

The Challenge: Ensuring Safety in Stacker and Reclaimer Operations

Stackers and reclaimers are indispensable for stacking raw materials and reclaiming them for processing. However, they operate in environments fraught with challenges, such as dust, low visibility, and tight coordination when sharing tracks. Collisions, material jams, and misalignments can lead to costly downtime, equipment damage, and safety hazards.

A single collision between stackers and reclaimers can result in millions of dollars in losses due to downtime, repairs, and production disruptions. The burden of manually monitoring and preventing such incidents falls heavily on duty engineers, adding operational stress and increasing the risk of errors.

Traditional safety systems provide a basic level of support but fall short of meeting the demands of modern operations:

- Operator Dependency: Human reaction times and decision-making are prone to delays and errors.

- Limited Automation: Existing systems rely heavily on alarms and sensors, requiring constant human intervention.

- Environmental Challenges: Dust, poor visibility, and obstructions compromise traditional sensors’ accuracy and reliability.

These limitations highlight the need for a system that can proactively ensure safety and operational efficiency, without overburdening operators and engineers.

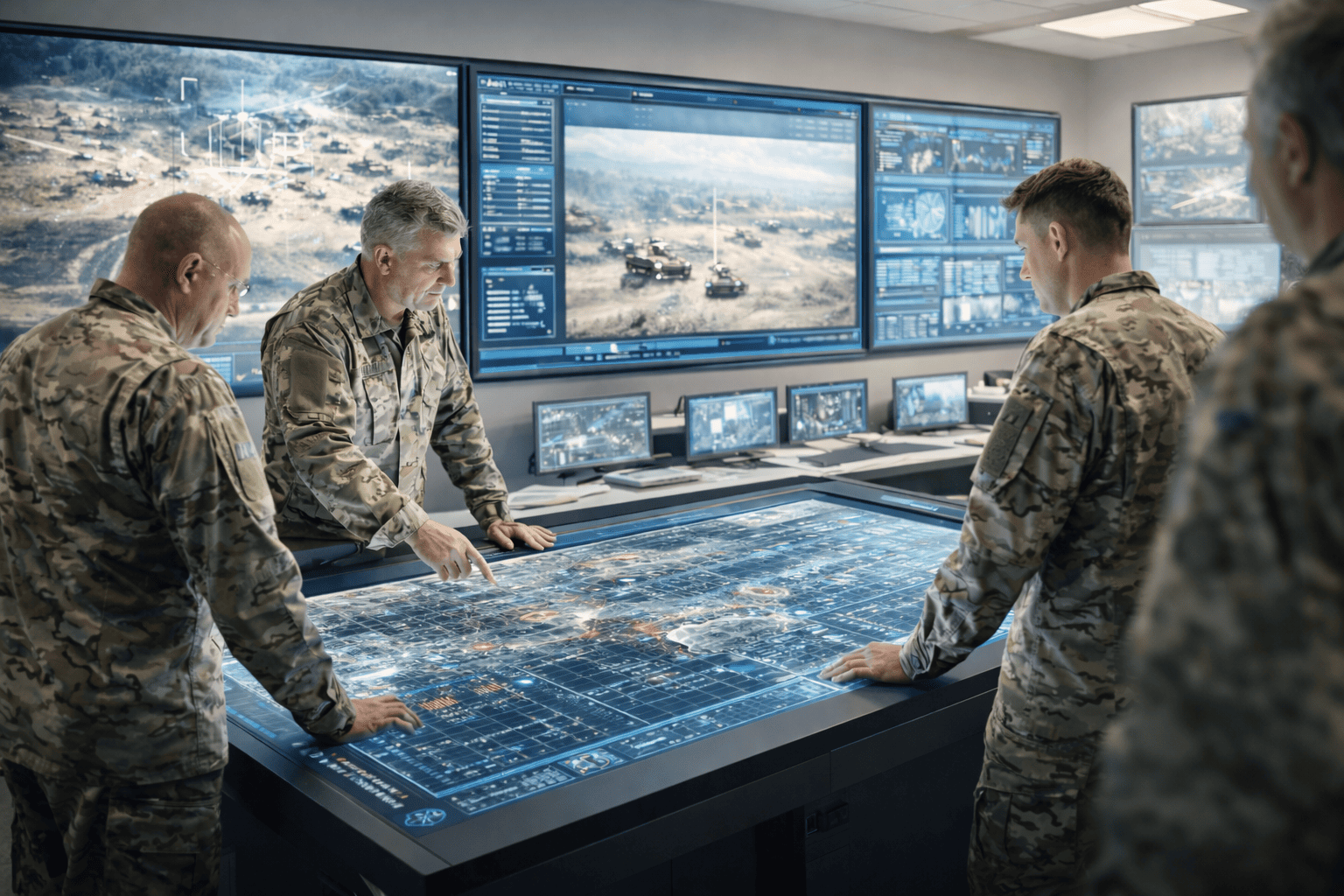

The Solution: AI and Computer Vision-Based Systems

Advanced solutions leveraging computer vision, artificial intelligence, and real-time analytics are transforming industrial operations. These systems address traditional safety systems’ shortcomings while introducing proactive, automated capabilities that enhance operational safety and efficiency.

- Continuous Monitoring: Cameras integrated with computer vision algorithms provide real-time tracking of machinery movements.

- Object and Hazard Detection: AI and computer vision distinguish between machinery, obstacles, and environmental conditions, predicting potential risks with high precision.

- Collision Prevention: Automated systems halt machinery or adjust operations upon detecting risks, preventing accidents before they occur.

- Predictive Maintenance: AI analyzes data on wear and tear, enabling preemptive action before failures occur.

Enhanced Alerts: Real-time notifications powered by computer vision insights keep operators informed, ensuring timely interventions

Applications of AI and Computer Vision in stacker and reclaimer operations

By adopting AI and computer vision-based systems, industries can address multiple challenges and improve safety and efficiency across operations:

- Preventing Collisions: Computer vision systems predict collisions between stackers and reclaimers by analyzing speed, direction, and proximity. Immediate interventions reduce risks, saving millions in potential downtime and repairs. Its shown by the below image

- Monitoring Belt Surfaces: Detect wear, cracks, or debris on conveyor belts using vision-based analytics. Enable predictive maintenance to minimize failures and production disruptions.

- Detecting Skewness: Monitor skewness in stacker and reclaimer movements through real-time image analysis to ensure proper alignment. Prevent uneven material distribution and damage to machinery check the image below

- Handling Bucket Jams: Computer vision systems identify and alert operators to material jams in buckets, ensuring swift resolution and minimal delays.

- Operating in Harsh Environments: AI-powered systems function effectively in dusty, low-visibility conditions, ensuring continuous performance.

- Supporting Duty Engineers: Automation, supported by computer vision, reduces the need for constant manual intervention, easing engineers’ workload and allowing them to focus on strategic tasks.

Benefits of AI and Computer Vision Systems

The integration of AI and computer vision in stacker and reclaimer operations offers significant benefits for all stakeholders:

- Operators: Reduced stress and improved focus with real-time alerts and automated interventions.

- Management: Minimized downtime, enhanced operational efficiency, and reduced costs from maintenance and accidents.

- Workers: Safer environments with fewer risks of accidents and injuries.

- Organizations: Improved productivity, streamlined processes, and significant cost savings.

As industries evolve, solutions of computer vision and AI are becoming indispensable. These technologies address safety challenges, optimize operations, and reduce the burden on human operators, ensuring a future where technology supports both efficiency and safety. Organizations like Valiance Solutions use it for diverse challenges, such as industrial surveillance, monitoring urban environments, and optimizing industrial processes. This versatility highlights its transformative potential. Valiance’s expertise exemplifies its commitment to scalable solutions that enhance safety and efficiency. By combining AI-powered insights with real-time interventions, Vision Analytics empowers industries to achieve safer, more reliable operations.